Applications

Laser welding is a new welding process that is still under development. Laser welding can be interesting in various industries, such as:

- Food & Pharma

- Food industry

- Interior and furniture industry

- Mechanical engineering

Manual laser welding is currently less suitable for heavier construction work because the penetration depth is still limited. In addition, deposition rates are low when welding with filler material.

On this page, you will find examples of weld seams and structural elements that have been welded with the laser.

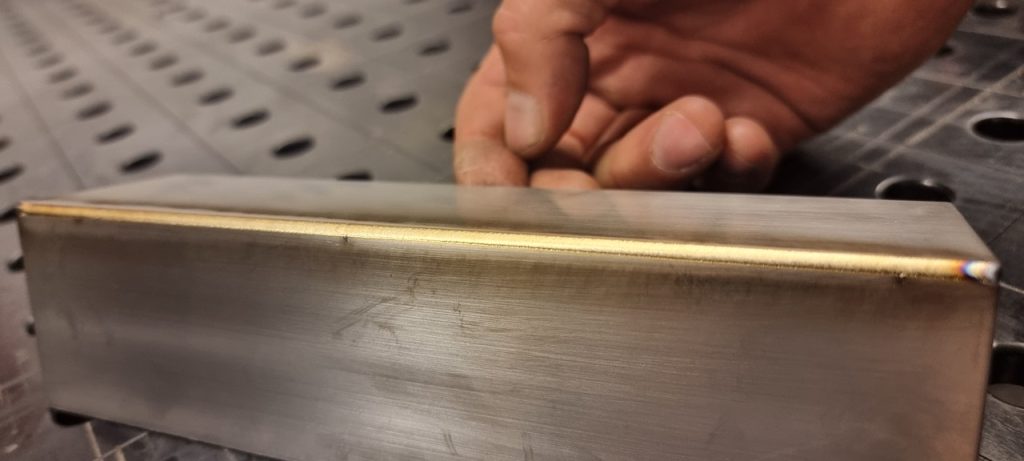

Inside fillet welds

Making inside fillet welds with the laser is very easy. The welding speed is very high, requiring virtually no post-treatment.

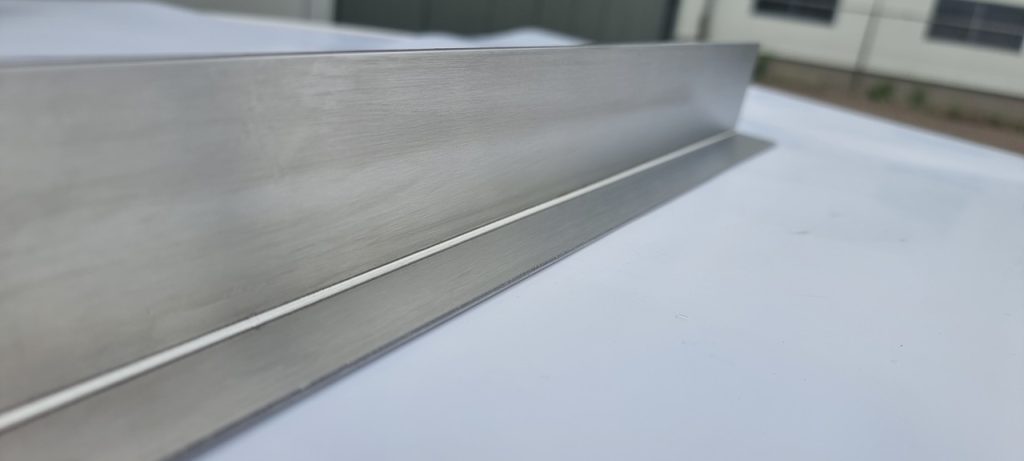

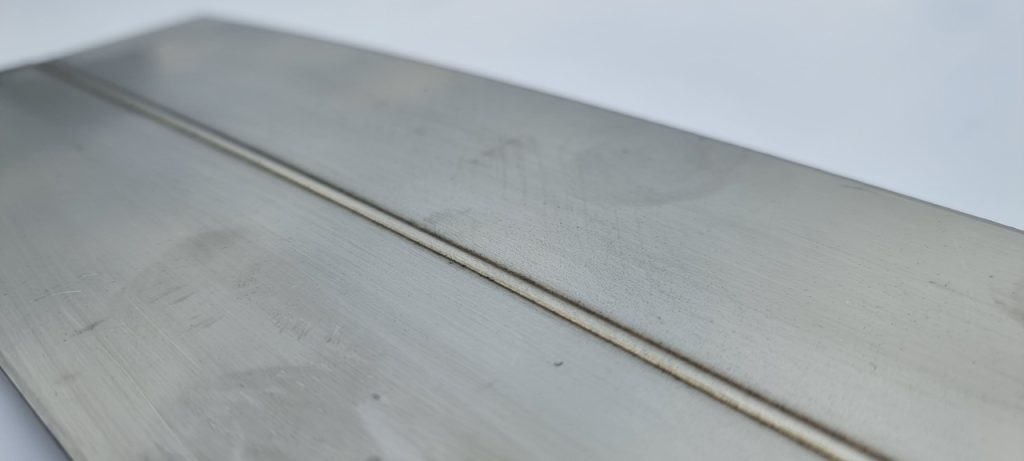

I-Seam

For laser welding of an I-seam, it is wise to use a stop along which the welding gun can be moved. By using the stop it is easy to achieve a good result.

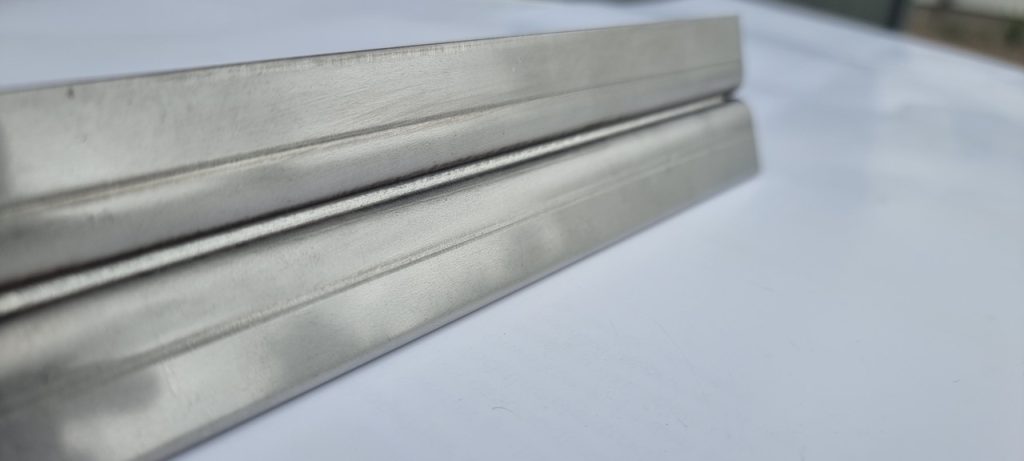

In the gutter

Welding a bent plate, a wall, or two bent plates together is easy. Welding with filler metal is then required.

Outside corner welds

By choosing the right attachment on the welding gun, outside fillet welds can also be easily made.

T joint in tube

For welding connections in profiles and tubes it is necessary that the preparation is optimal. The gap should be minimal and consistent.